What is a damp proof membrane and how does it work? Our article demystifies the types of DPM, installation processes, and the benefits of ensuring your property is adequately damp proofed.

What is a Damp Proof Membrane?

A damp-proof membrane (DPM) is a significant part of the construction sector. It functions to protect buildings from dampness originating from the earth. Dampness within the walls of structures can generate a variety of issues, such as harm to internal finishes, the formation of mould and unpleasant, musty odours. More often than not, damp-proof membranes, frequently shortened to DPMs, are incorporated into construction projects to tackle these humidity-related issues.

These membranes produce an effectual barrier that halts moisture from the ground from infiltrating interior spaces via the walls or the floor of a structure. The damp-proofing membranes are generally made up of impervious substances such as high-density polyethene or polyvinyl chloride, which offer excellent resistance to the passage of water or water vapour. The correct installation process is a key determinant of a DPM's efficacy.

This process typically includes the positioning of the DPM on a surface that is smooth and free from any damage. This is to avoid puncturing the membrane, which would consequently undermine its ability to prevent moisture.

Any defects or punctures in the damp-proof membrane's material could allow moisture to infiltrate, defeating the purpose of the DPM. Therefore, careful installation is a necessity to guarantee that the structure is effectively safeguarded against potential moisture-related damages.

How Does a Damp Proof Membrane Work?

A damp-proof membrane (DPM) is a critical component in the construction of both commercial and residential buildings. It is designed to provide an impermeable barrier that locks out moisture from the ground, preventing it from penetrating building surfaces such as floors and walls.

This barrier prevents the upward migration of moisture through the capillaries within walls or floors, a phenomenon commonly known as rising dampness. The primary function and purpose of DPM is to guard against the detrimental effects of moisture.

When moisture finds its way into a building, it can cause a myriad of problems, including rot, mildew, and even structural damage if left unchecked. It is therefore crucial that a DPM is installed correctly to provide full protection against these potential issues. The process of installing a DPM requires meticulous planning and application.

The membrane is typically laid beneath concrete slabs during the initial construction stages or integrated within the structure of the walls. The installation process involves continuous overlapping of the membrane sheets. The joints are then sealed to create a seamless, leak-proof barrier that efficiently locks out moisture. The installation process's precision is extremely important as any weak points or gaps can allow moisture to seep through.

Therefore, it is always recommended to involve skilled, experienced personnel in this task. If installed correctly, a damp-proof membrane can effectively halt rising dampness and subsequently extend the lifespan of a building. This not only safeguards the building's integrity but also creates a healthier living or working environment by preventing the proliferation of mould and mildew.

To sum up, damp-proof membranes play a vital role in building construction. It serves as an impermeable barrier that stops ground moisture from creeping into walls and floors. Hence, DPMs are indispensable for maintaining the structural robustness of any building and for preserving its aesthetics over time. With correct installation and maintenance, a DPM can be an effective line of defence against the damaging effects of moisture.

What Is the Difference Between Damp Proof Membrane and Waterproof Membrane?

Although the expressions 'damp proofing' and 'waterproofing' are frequently mixed up, it's important to distinguish between a damp proof membrane and a waterproof membrane. Both of these come into play to stop water from seeping into building materials, however, their coverage level and protection techniques are not the same. A damp-proof membrane, as previously clarified, is a barrier engineered to obstruct the vertical climb of water within the walls or floors. This is known as rising damp.

In contrast, a waterproof membrane is constructed to block water infiltration from any direction. This implies that waterproof membranes deliver far more comprehensive protection. They are usually deployed in situations where they're exposed to relentless immersion or extremely damp conditions such as in swimming pools or bathrooms underneath tiles.

To sum up, although both technologies prevent water damage, their use and level of protection vary. A damp-proof membrane acts against the upward movement of water and is typically employed in domestic buildings to guard against rising damp. It can't prevent water penetration from all directions like a waterproof membrane. Conversely, a waterproof membrane is utilised when a complete wet-proofing solution is required. It provides an all-rounded defence against water infiltration from all sides, making it ideal for coping with core wet applications.

What are the Most Common Materials Used for Damp Proofing?

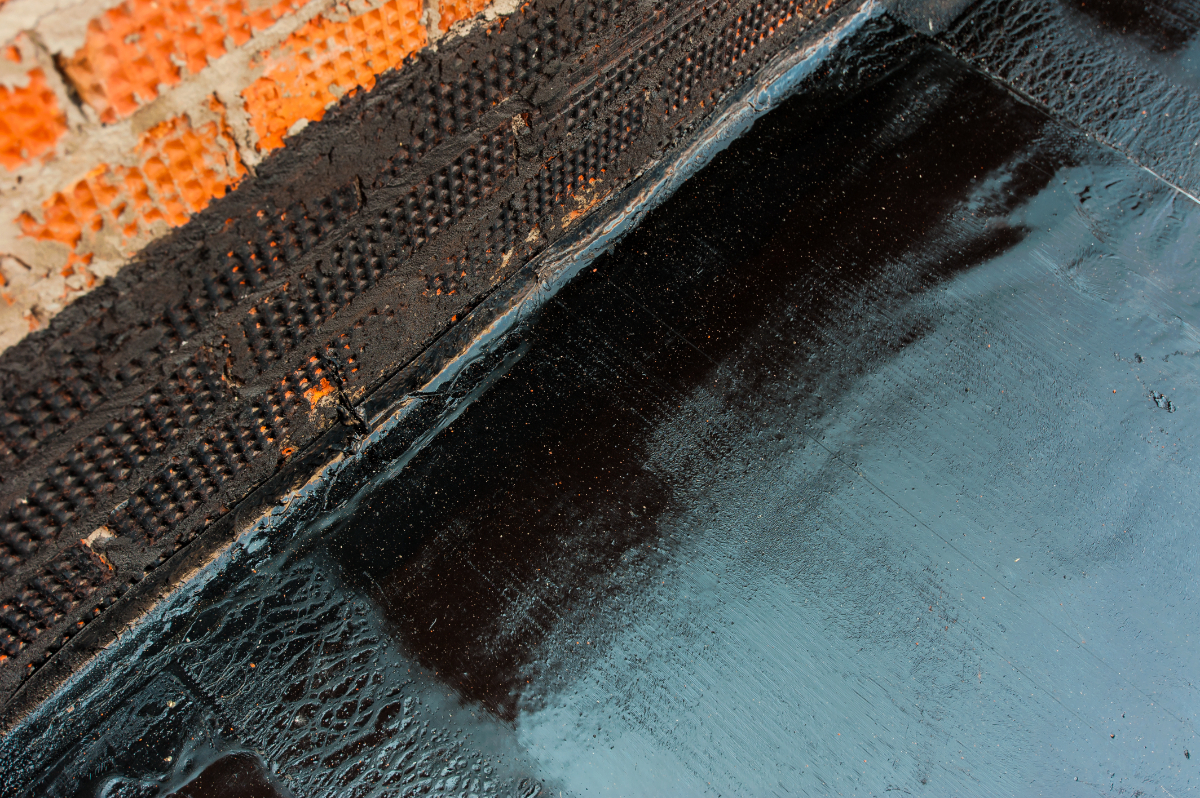

In the realm of damp proofing, there are three common materials that reign supreme: bitumen, plastic sheets, and liquid coatings. Bitumen is a material that is impervious to water and hence is often employed in damp proofing.

It is characterized by its malleability when heated and its solidification upon cooling. Its pliability when hot makes bitumen sheets an ideal material for under-floor damp proofing.

When applied under flooring, the sheets harden as they cool, forming an effective moisture barrier that protects against rising damp and groundwater. The use of bitumen provides a sturdy, waterproof shield underfoot, safeguarding your home or property from the potentially damaging effects of dampness.

Secondly, plastic sheets – specifically High-Density Polyethylene (HDPE) and Polyvinyl Chloride (PVC) – are prevalent materials used for Damp Proof Membranes (DPMs). These sheets serve as a barrier to prevent moisture from permeating into building structures.

These materials are typically employed under concrete floor slabs or integrated within walls to prevent moisture intrusion. Renowned for their exceptional water-resistant properties, HDPE and PVC sheets are near impermeable to water, guaranteeing that your property remains moisture-free. Finally, the third frequent material of choice in damp proofing is liquid coatings. These coatings can be applied with either a brush or a roller, forming a waterproof layer on finished building surfaces.

By consolidating a moisture barrier on a property's external and internal surface, liquid damp-proofing coatings amplify the building's defences against dampness and further make sure the structural integrity and general look of a property are maintained. This method of damp proofing not only reduces dampness but also improves the aesthetic appeal of the building.

These key materials – bitumen, plastic sheets, and liquid coatings – are chosen for their superior damp-proof qualities, offering robust protection against dampness. By using these in damp proofing, your home or construction project is well-guarded against the harmful effects of moisture.

How Long Does Damp Proof Membrane Last?

A damp-proof membrane (DPM) is a critical component in the construction process. Its role is to shield buildings from dampness-related complications. When contemplating the use of a DPM, its durability is of vital importance. If correctly installed and of superior quality, such a membrane can serve reliably for many decades. The life expectancy of a DPM is not fixed. It varies based on multiple considerations such as the membrane's quality, installation, and environmental conditions.

However, often the lifespan of a DPM coincides with the longevity of the building itself, underpinning the importance of choosing a high-quality product. Despite the intended longevity of these membranes, certain situations may negatively affect their lifespan. Instances of accidental harm, subpar installation, or the use of poor-quality materials can drastically impair a DPM's performance.

Therefore, while damp-proof membranes are created with long-term use in mind, regular inspections and upkeep are mandatory. Regular maintenance not only ensures that your membrane remains in optimal condition, but also that it continues to offer protection against moisture issues over time. This becomes particularly important in areas with adverse weather conditions, or in older buildings which are more prone to damp-related issues.

So, when considering your construction project or renovations, taking into account the durability and maintenance of your DPM aids in protecting and extending the lifespan of your building. The prime objective is to choose a high-quality, durable membrane and ensure its proper installation and maintenance. This forms the bedrock for preventing moisture-related problems and thus ensuring the longevity of your structure.

At Above Water Damp Proofing Ltd we are trained professionals when it comes to damp. We understand that damp removal and damp-proofing your property can be costly - which is why we provide a range of damp-proofing services at a fair price. Learn more about damp proofing in Windsor, Slough, Berkshire & Surrey.